blank

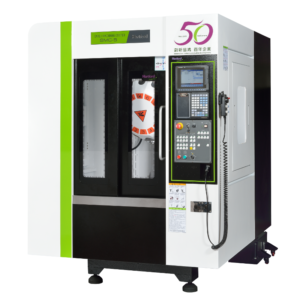

Hartford's 5A-650 is gantry designed machine with a rotating and tilting 650mm diameter table, available in 4 + 1 or true 5 Axis simultaneous machining configuration.

5A-600T(F)/5A-800T(F) high speed bridge type construction

- The special design of great span between Y-axis linear guideways drasticakly increases structural rigidity and resists heavy cutting load.

- With the additional pin on the bearing housing, higher transmission rigidity can be achieved.

- With thermal symmetry and heat isolation design, the heat thermal can be isolated to 97%.

- With the use of toplogy technology to conduct an optimum structrual analysis, a light-weight structure can be achieved.

- Unveiled at EMO 2017 5A-65E(F)

- X-axis guide ways are set on stepped bed

- Full-support design on Y-axis

- Oversized design on base

- Overlap design on 3-axis

- i-Tech spindle(opt)

- Exclusive smart functions for self-designed and manufactured high speed 24,000rpm spindle is available to integrate various smart functions such as i-Diagnosis, i-Compensation, i-Balance and i-Protections that provide safety protection of the spindle, increase the spindle accuracy and reduce down time.

Static rigidity and structure analysis

- Static rigidity and machine structure are analyzed by ANSYS to confirm structure design quality and safety for optimum performance.

Roller type linear guideways on 3 axes

- The linear contact between the rolling body of the roller and the sliding block causes a tiny elastic deformation under a high load condition. This makes high accuracy, heavy load resistance and lifespan possible.

Thermal growth control on 3 axes(opt)

- The parts in 3-axis feed system, such as the motor base, ballscrews, nuts and bearing are completely cooled to remove thermal deformation while ensuring the positioning accuracy of the machine(Features may vary by model, please check with sales person).

Model identification

- T: Twin arm(Twin arm supported rotary table)

- F: Four(4+1 axis control function)

- TF: Twin arm+Four

Specifications of 5A series

| MODEL | 5A-650 | 5A-65E | 5A-650F | 5A-65EF | 5A-600T |

|---|---|---|---|---|---|

| Table Size (mm) | φ650 | φ650 | φ650 | φ650 | φ600xW500 |

| Max. table load Vertical (kg) | 250 | 250 | 300 | 200 | 500 |

| Max. table load Horizontal (kg) | 300 | 300 | 200 | 300 | 500 |

| X Axis Travel (mm) | 650 | 650 | 660 | 650 | 650 |

| Y Axis Travel (mm) | 520 | 520 | 550 | 520 | 1000 |

| Z Axis Travel (mm) | 460 | 460 | 460 | 460 | 600 |

| Spindle nose taper | ISO40/HSK-A63 | ||||

| Spindle speed(DDS) (rpm) | 10000 opt.12000/15000/20000 | ||||

| Spindle speed(Built-in)rpm) | opt. 24000 | ||||

| Slideways | Linear guide way | ||||

| Controller | Fanuc Oi-MF / Mitsubishi M80A | ||||

| Rapid traverse rate(X/Y/Z) (m/min) | 36/36/36 | ||||

| Tool storage (pcs) | 16 opt. 24/30/40/60 | ||||

| MODEL | 5A-600TF | 5A-800T #40 |

5A-800T #50 |

5A-800TF #40 |

5A-800TF #40 |

|---|---|---|---|---|---|

| Table Size (mm) | φ600xW500 | φ800 | φ800 | φ800 | φ800 |

| Max. table load Vertical (kg) | 500 | 600 | 600 | 600 | 600 |

| Max. table load Horizontal (kg) | 500 | 600 | 600 | 600 | 600 |

| X Axis Travel (mm) | 650 | 800 | 800 | 800 | 800 |

| Y Axis Travel (mm) | 1000 | 1200 | 1200 | 1200 | 1200 |

| Z Axis Travel (mm) | 600 | 600 | 600 | 600 | 600 |

| Spindle nose taper | ISO40/HSK-A63 | ISO50/HSK-A100 | ISO40/HSK | ISO50/HSK

A100 |

|

| Spindle speed(DDS) (rpm) | |||||

| Spindle speed(Built-in)rpm) | #40 opt. 24000 | #50 opt. 12000 | opt. 24000 | #50 opt. 12000 | |

| Slideways | Linear guide way | ||||

| Controller | Fanuc Oi-MF / Mitsubishi M80A | ||||

| Rapid traverse rate(X/Y/Z) (m/min) | 36/36/36 | ||||

| Tool storage (pcs) | 16 opt. 24/30/40/60 | ||||

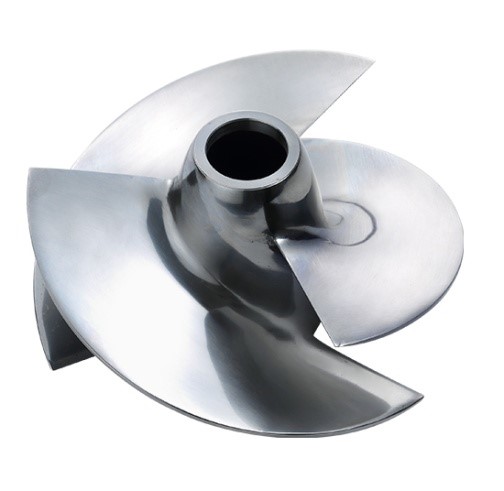

Application Examples: