blank

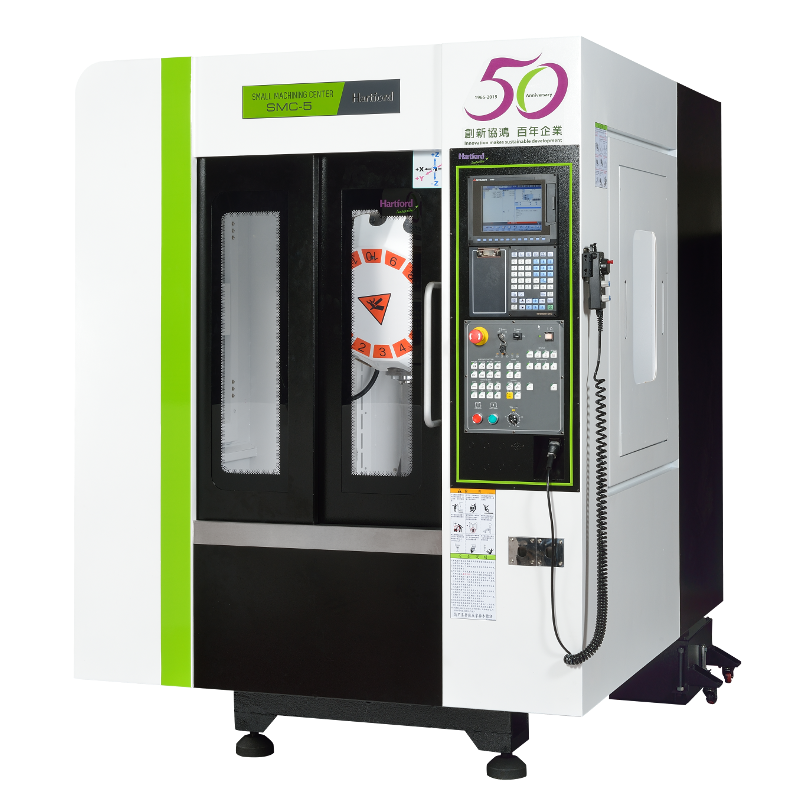

SMC-5: An efficient compact machining center specially designed for 3C industries

- Massive base & column: The heavily constructed base and column with scientific rib reinforce dramatically upgrade structural strength and rigidity.

- No counter balance: The oversized Z axis ballscrew powers the head stock moving up and down rapidly and smoothly, displaying the speed of tapping center and rigidity of machining center.

- High quality cast iron: All structure parts are manufactured from high quality Meehanite cast iron, and stress relieved for outstanding material stability.

- Linear ways on 3 axes: The linear ways on X,Y and Z-axes are high grade and exhibit a greater span design to achieve maximum stability during machining.

Specifications of SMC series

| MODEL | SMC-5 |

|---|---|

| Table Size (mm) | 600×400 |

| Max. table load (kg) | 250 |

| X Axis Travel (mm) | 500 |

| Y Axis Travel (mm) | 400 |

| Z Axis Travel (mm) | 300 |

| Spindle nose taper | ISO30 |

| Spindle speed(DDS)(rpm) | Mitsubishi: 12000opt.15000/24000

FANUC: 10000 opt. 15000/20000 |

| Slideways | Linear guide way |

| Controller | Fanuc Oi-MF / Mitsubishi M80A |

| Rapid traverse rate(X/Y/Z) (m/min) | Mitsubishi: 50/50/50, FANUC: 48/48/48 |

| Tool storage (pcs) | 14/21 (Turret type) |

Application Examples: