blank

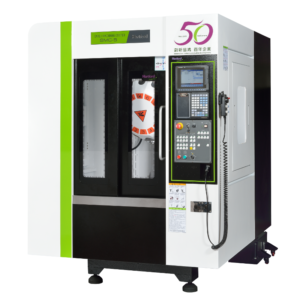

This series is designed to give you the best price to value ratio while still maintaining Hartford’s stringent quality inspection.

+ Linear guide way

+ The rapid feed rate is 40/40/32 m/min for X,Y,Z axes (opt.).

+ Eco-friendly design

High efficiency

- The rapid feed rate is 40/40/32 m/min for X,Y,Z axes (opt.).

- Such high speeds reduce non-cutting time and directly increase productivity.Better stability, high accuracy

- The rigid one-piece bed and wide column base are heavily ribbed to prevent twisting and distortion under even the most severe cutting forces.

- The find great Meehanite cast iron contributes to unparalleled damping characteristics.

- Incorporated oil fluid separation on casting design

- Eco-friendly design

- Efficient oil and fluid separation incorporated on casting design prevents cutting fluid deterioration.

- Once-piece casting design integrates chassis and chip disposal opening with base.

- No abutment on chassis.

- Leaking-free design.

- Heavy duty & precise linear guideways

- The linear guide on three axes are high grade, providing stability for heavy cutting

- High efficiency machining center

Specifications of F1/ LG series

| MODEL | LG-500 | LG-800 | LG-1000 | LG-1370 | LG-1570 |

|---|---|---|---|---|---|

| Table Size (mm) | 620×420 | 950×510 | 1150×510 | 1400×650 | 1600×650 |

| Max. table load (kg) | 500 | 500 | 700 | 1000 | 1000 |

| X Axis Travel (mm) | 520 | 800 | 1000 | 1300 | 1500 |

| Y Axis Travel (mm) | 420 | 510 | 510 | 700 | 700 |

| Z Axis Travel (mm) | 450 | 630 | 630 | 650 | 650 |

| Spindle nose taper | ISO40 | ||||

| Spidnle speed(Pulley) (rpm) | 8000 opt.10000/12000 | ||||

| Spindle speed(DDS)(rpm) | 10000 opt.12000/15000 | ||||

| Slideways | Linear guide way | ||||

| Controller | Fanuc Oi-MF / Mitsubishi M80A | ||||

| Rapid traverse rate(X/Y/Z) (m/min) | 30/30/24 opt.40/40/30 | ||||

| Tool storage (pcs) | A:24 opt. S:16 | ||||

Application Examples: